Fire Hose Advancer

Design project focused on enhancing fire safety equipment

Overview

The project focused on creating a device to help firefighters advance hoses during high-pressure operations while preventing kinks that restrict water flow. The design prioritized robustness, ease of use, and low-cost manufacturability, making it suitable for deployment in rural and underprivileged areas where resources are limited.

How the Design Works

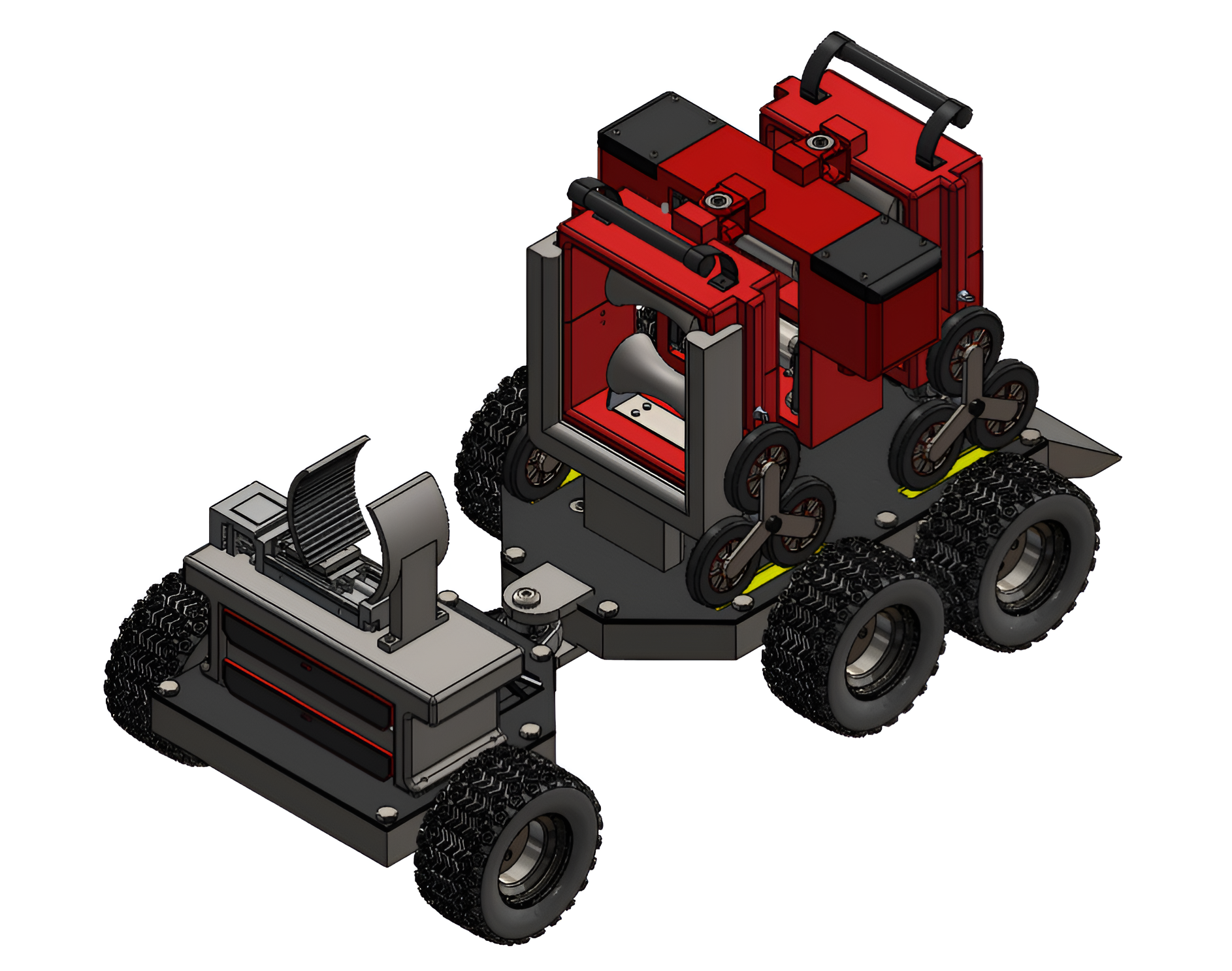

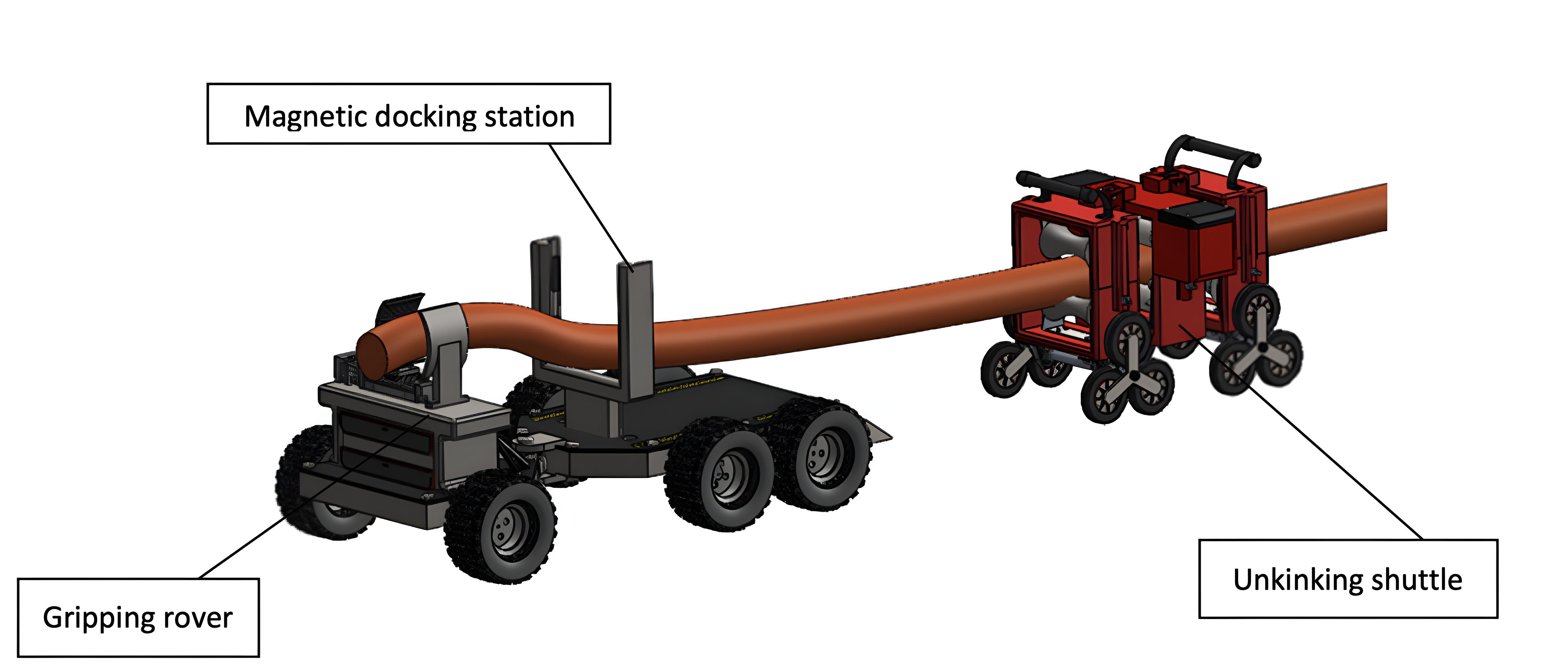

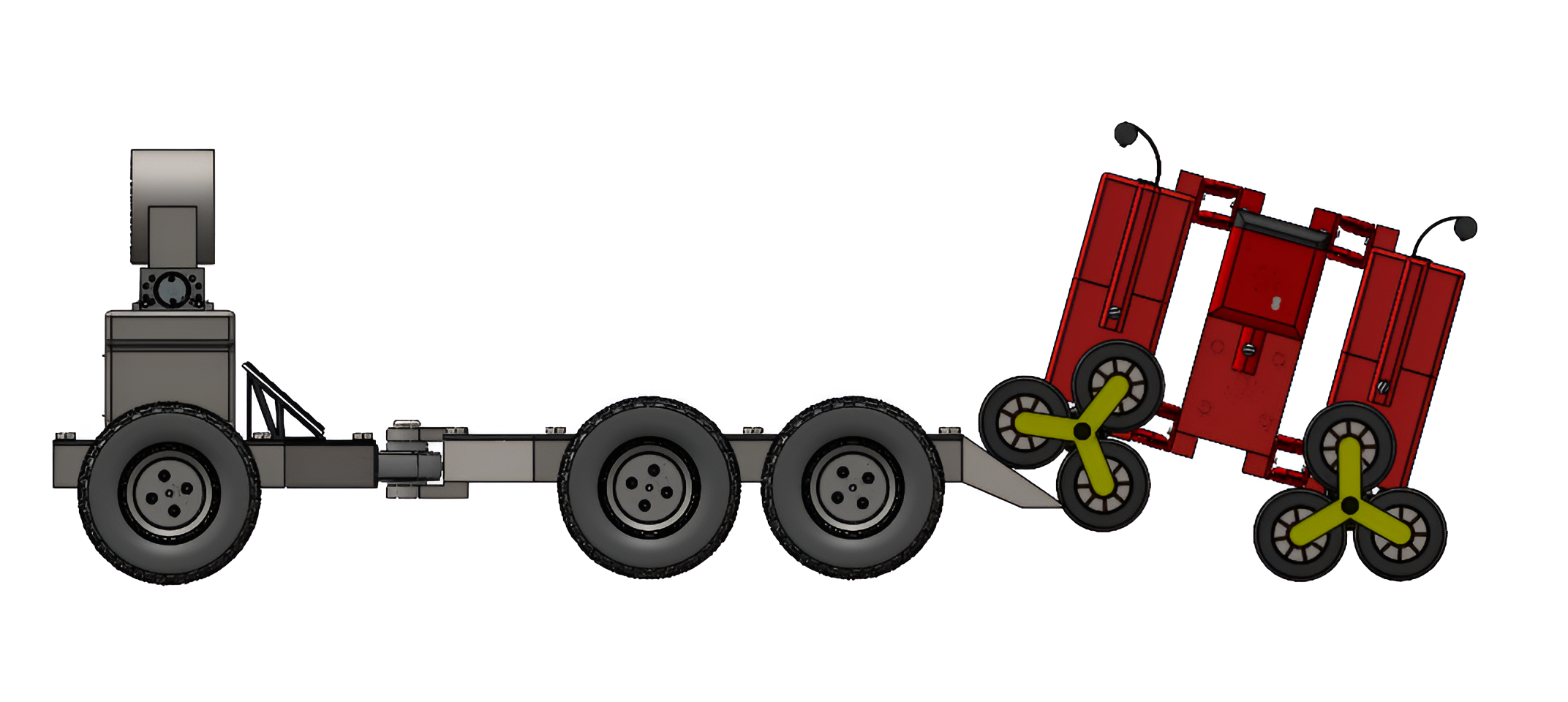

The system consists of two complementary modules — the Gripping Rover for hose advancement and the Unkinking Shuttle for kink removal. Together, they allow firefighters to advance hoses continuously, even in the presence of kinks.

Gripping Rover

- Two-module chassis with a central pivot for unpowered steering, keeping the device aligned without electronics.

- Six all-terrain wheels, with the front pair powered independently for traction.

- Water-resistant, heat-shielded battery housing with quick-release access.

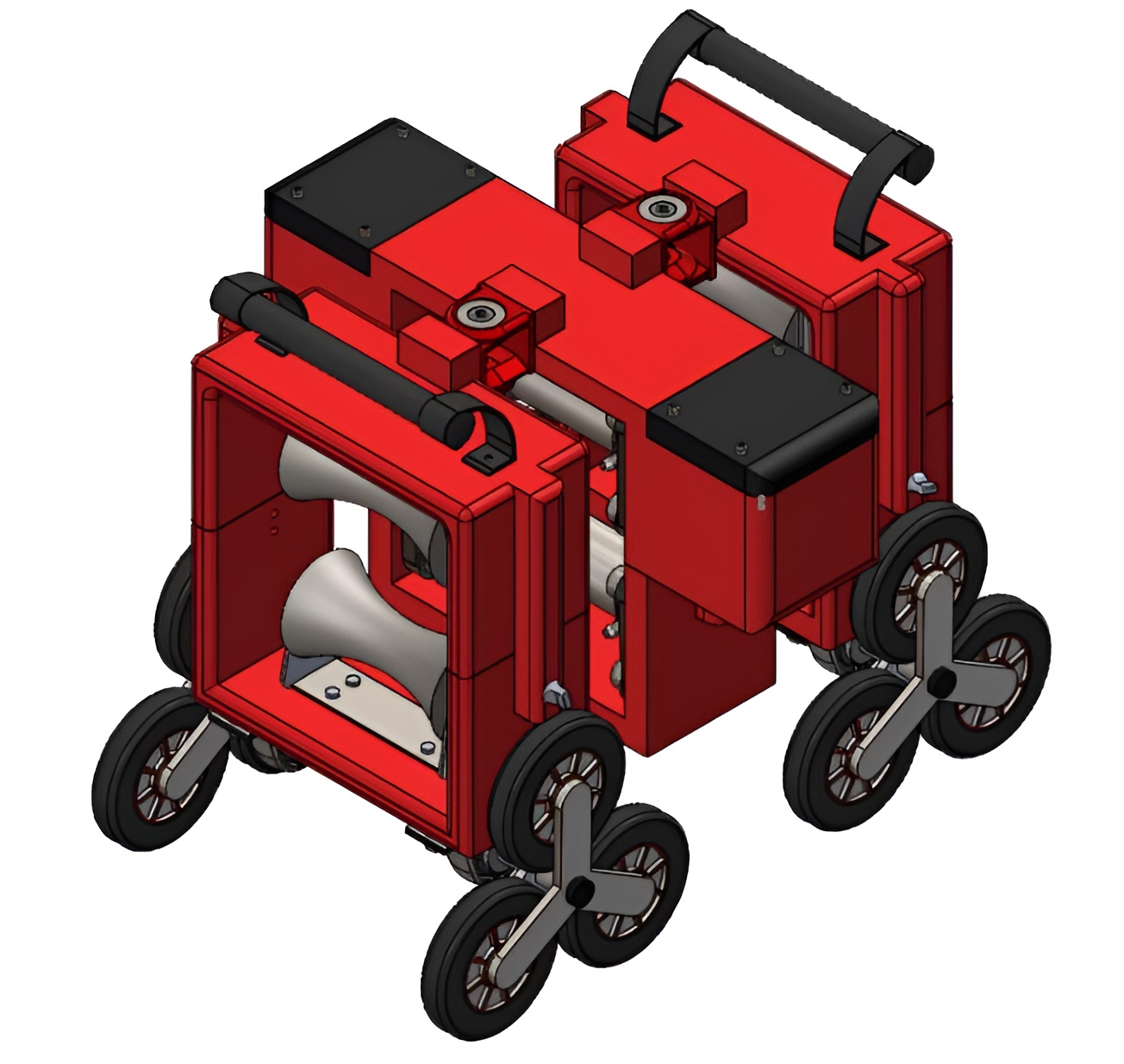

Unkinking Shuttle

- Three modules: a powered central roller unit and two unpowered alignment modules.

- Hinged connectors allow the shuttle to snake along bends until it reaches a kink.

- Magnetic docking system for secure storage and easy deployment.

Triangular Wheels

- Each assembly uses three rotating sub-wheels.

- Provides “stepping” motion to climb over rough terrain or obstacles.

Hose Grip

- Concave arms shaped for 45 mm and 64 mm hoses.

- Rubber lining for high friction and slip prevention.

- Open-top actuator design for quick mounting and release.

Sustainability Considerations

The Fire Hose Advancer supports three UN Sustainable Development Goals (SDGs):

-

SDG 2: Zero Hunger – In rural and under-resourced areas, firefighting relies on self-organised efforts. The device simplifies hose advancement for minimally trained individuals and resolves kinks automatically, allowing communities to better protect crops and reduce famine risks caused by wildfires.

-

SDG 12: Responsible Consumption and Production – Modular design and standardised off-the-shelf components reduce energy demands during manufacturing and simplify repairs. The chassis uses recycled aluminium, which is lightweight, durable, and infinitely recyclable, extending the device’s lifespan and supporting a circular economy.

-

SDG 15: Life on Land – Wildfires destroy forests, wildlife habitats, and agricultural land globally. This device allows a single firefighter to advance hoses efficiently, while the automatic unkinking system reduces downtime, improving wildfire response and protecting ecosystems.

Results

The project achieved a grade of 82%. Key feedback highlighted:

- A clear and systematic evaluation process (Selection Matrix).

- A comprehensive design overview with detailed CAD models.

- Strong operational clarity, showing exactly how the device functions.

- Well-integrated sustainability considerations linked to SDGs.