2-Axes CNC Lathe

Mechanical design project for a compact classroom CNC lathe

Overview

Designed a compact 2-axes tabletop CNC lathe capable of precision machining aluminium and polymer workpieces up to 40 mm in diameter and length. Features a 3-jaw chuck, achieves high accuracy (≤8 μm deflection at the cutting edge), and fits within a 625 × 250 mm footprint. Ideal for classroom demonstrations, small-scale prototyping, and educational workshops.

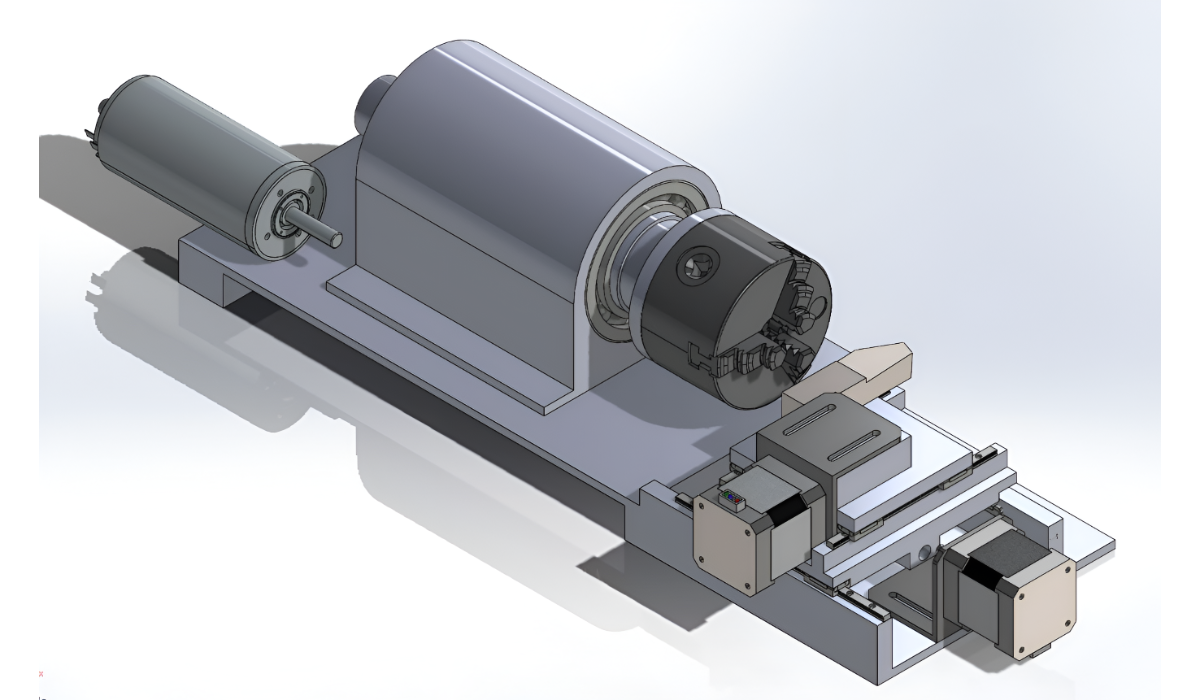

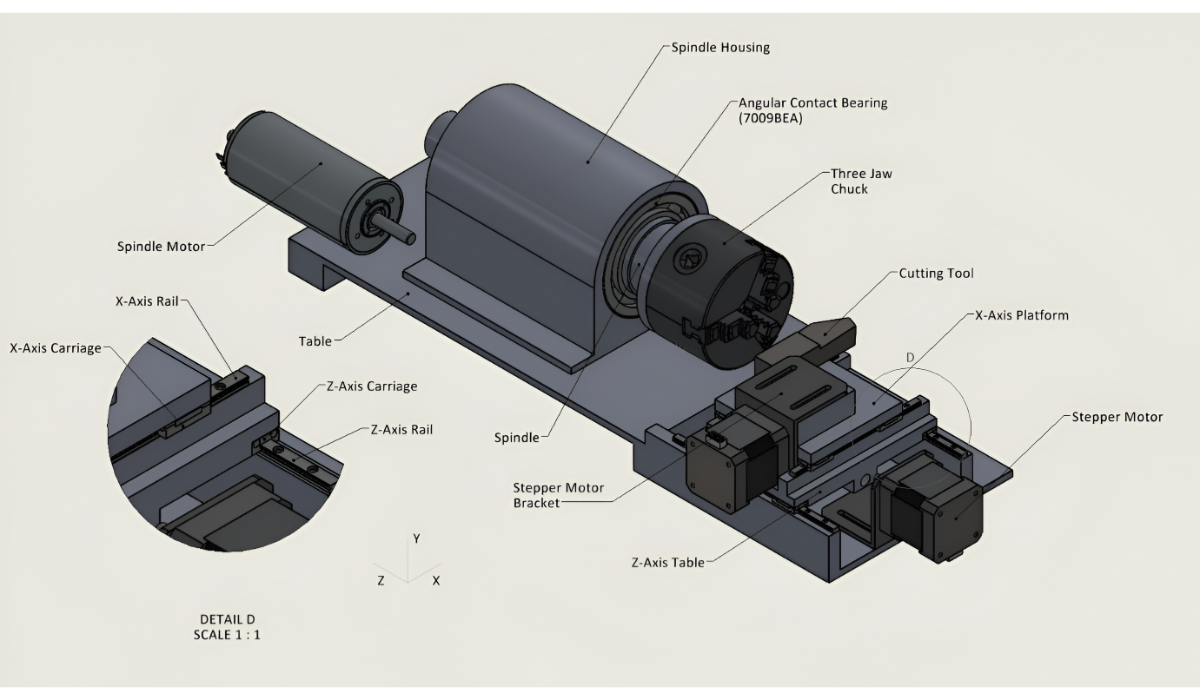

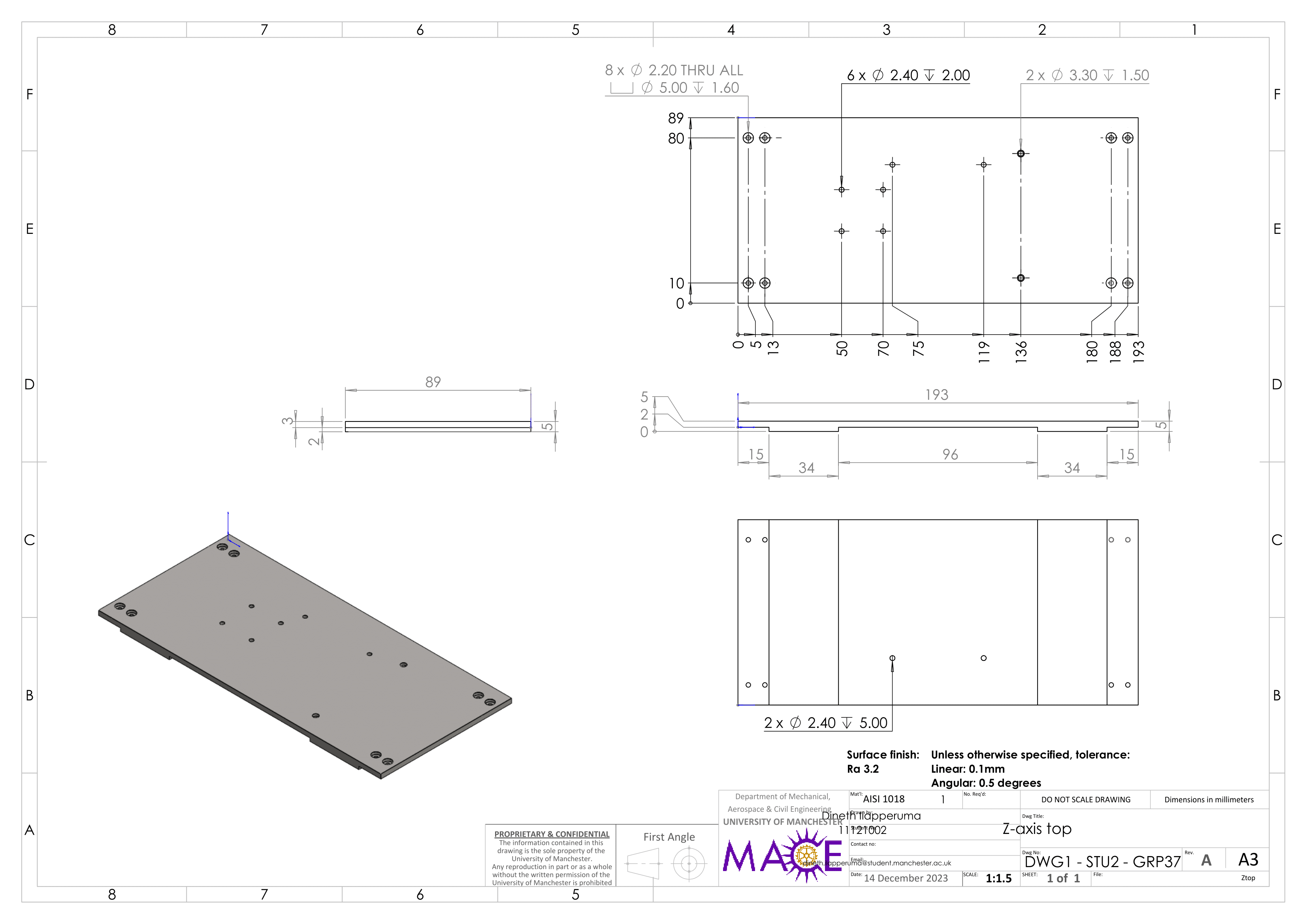

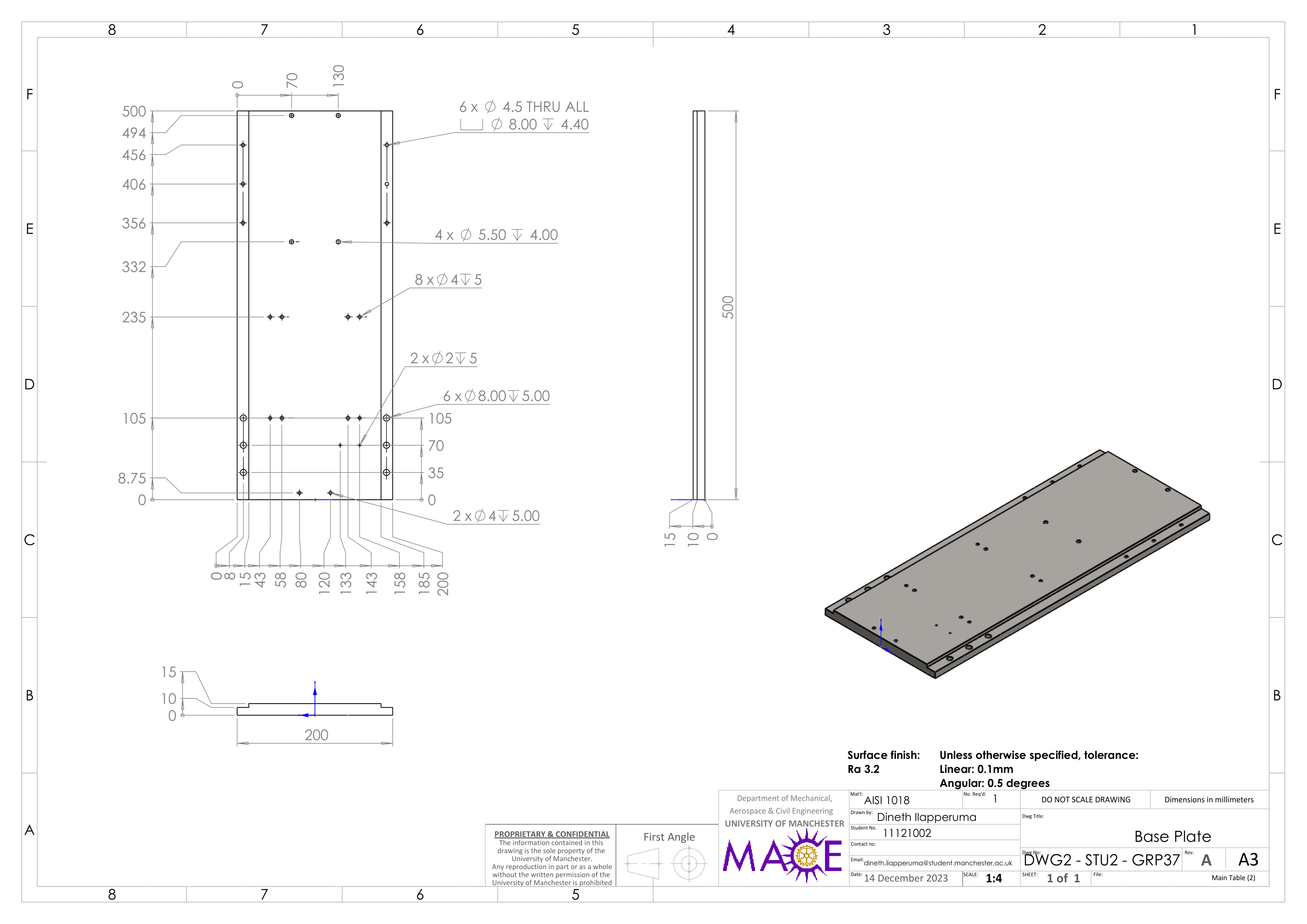

CAD model (left) and detailed engineering drawing (right) of the 2-Axes Tabletop CNC Lathe.

Design Process

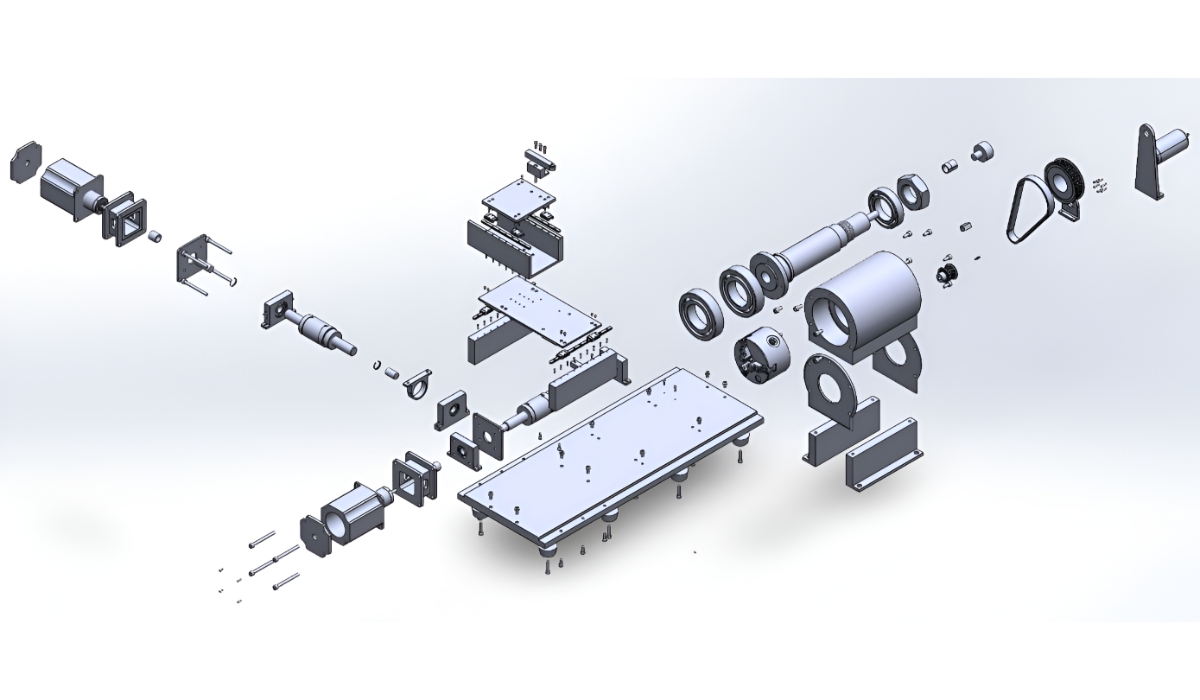

The lathe was developed by focusing on three main subsystems: the spindle, X-stage, and Z-stage. Key design considerations included minimizing deflection, ensuring rigidity, and selecting components capable of withstanding calculated cutting forces.

- CAD Modelling: Used SolidWorks for complex geometry and multi-component assembly.

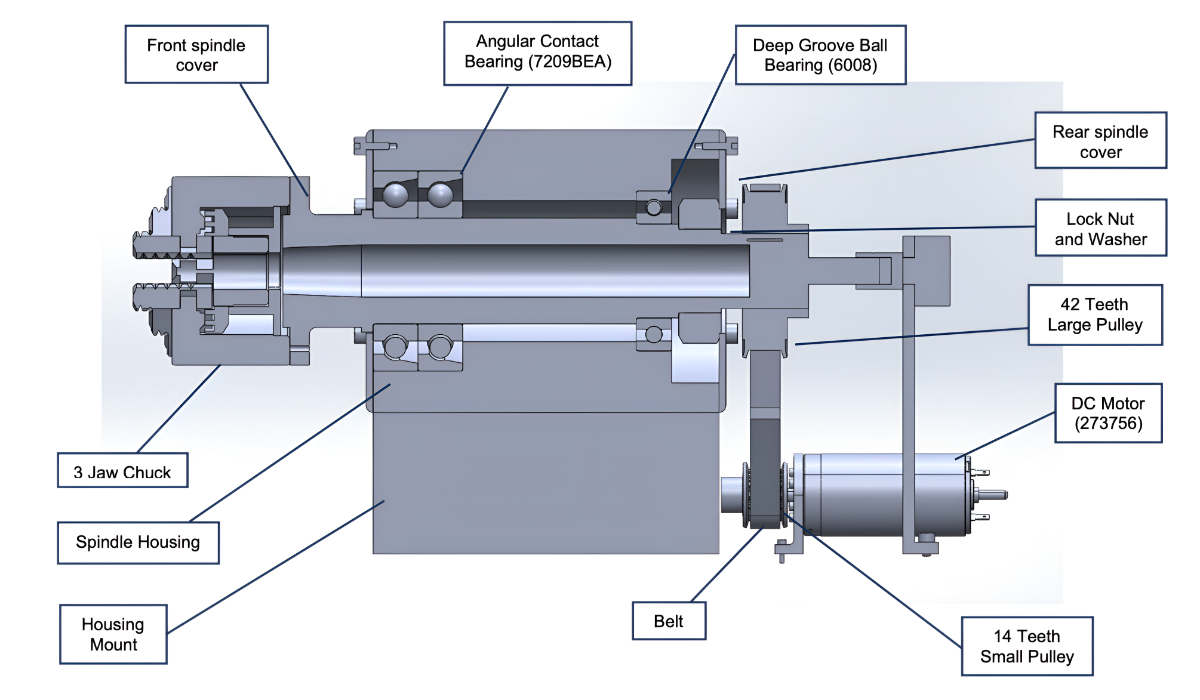

- Spindle & Bearings: Calculated cutting forces determined bearing load ratings. Spindle diameter and bearing placement were optimized to limit deflection to ≤8 μm.

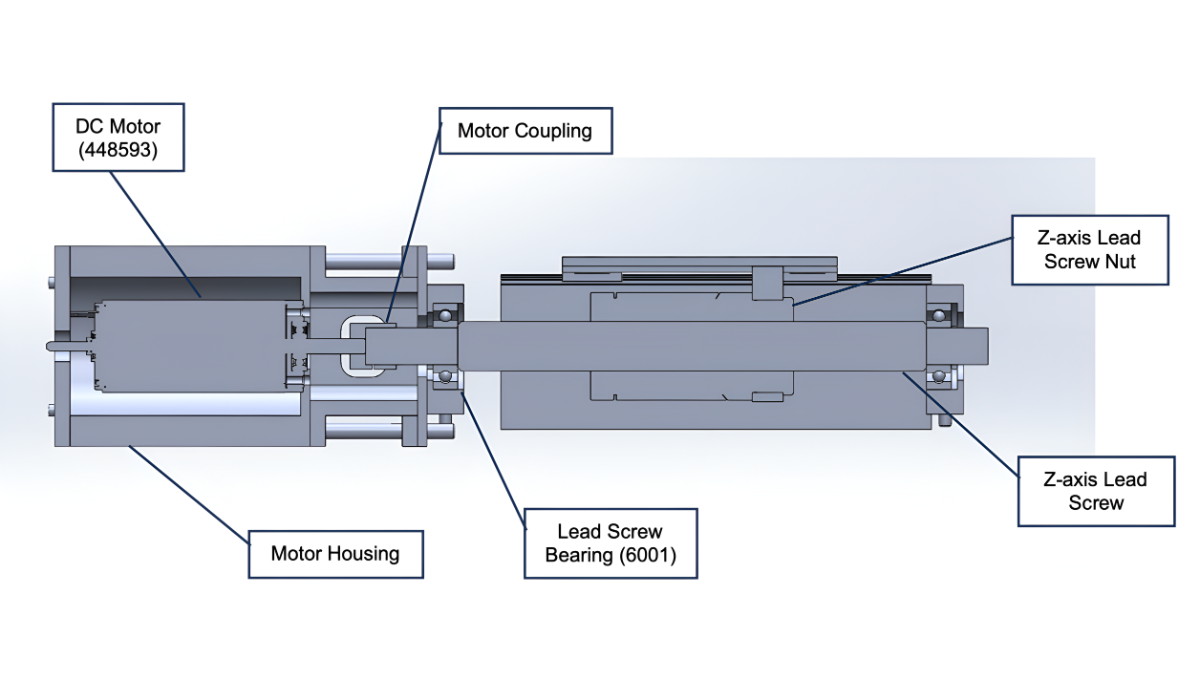

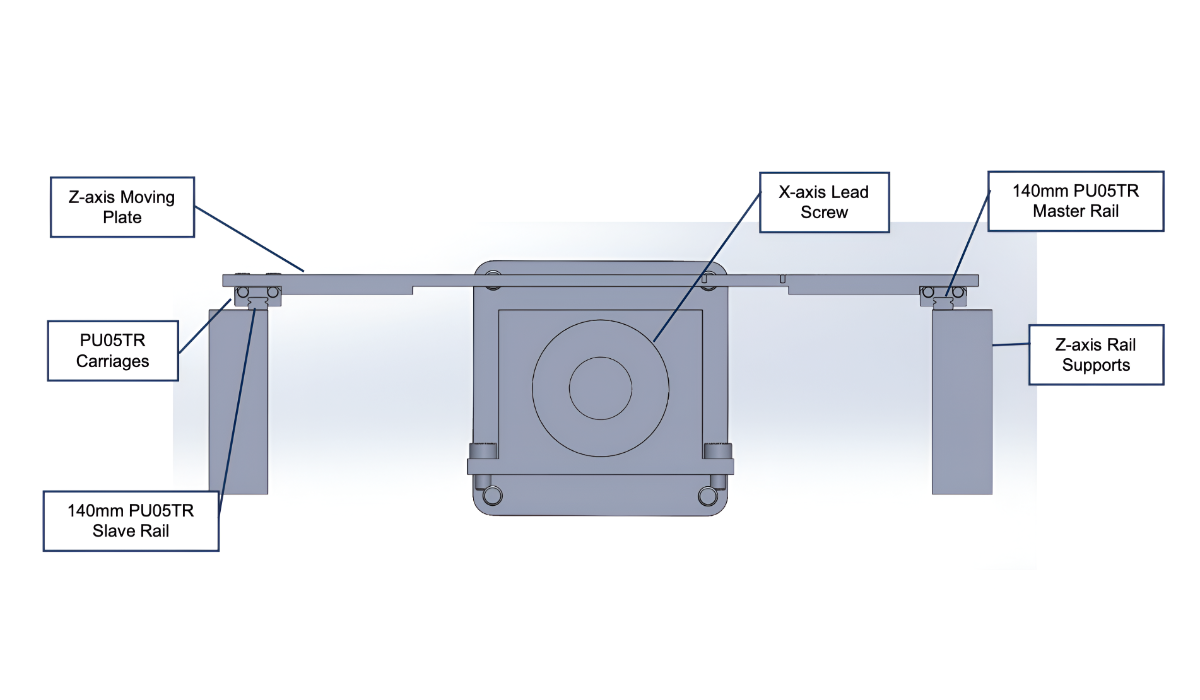

- X and Z Stages: Linear rails and lead-screws were selected to handle vertical and axial loads, ensuring smooth, precise motion.

- Drive Train & Motors: Pulley-belt spindle drive and DC motors chosen to meet torque and speed requirements.

- GD&T & Modularity: Applied geometric dimensioning and tolerancing on all drawings. Designed for easy maintenance and future upgrades.

Cross-sectional views (top) and corresponding engineering drawings (bottom) of the Z-Axis Table.

Results

- Achieved design deflection under 8 μm at the cutting edge.

- SolidWorks assembly confirmed proper alignment and clearances.

- Component selection verified through calculations for bearing load, spindle torque, and lead-screw stresses.

- Final CAD models demonstrated a compact footprint suitable for small prototyping environments.

- Design modularity allows easy maintenance, repair, and upgrade of X/Z stages and spindle components.

Cross-sectional (left) and exploded (right) views of the complete CNC lathe assembly.